1A: Onshape Fundamentals - Section 1

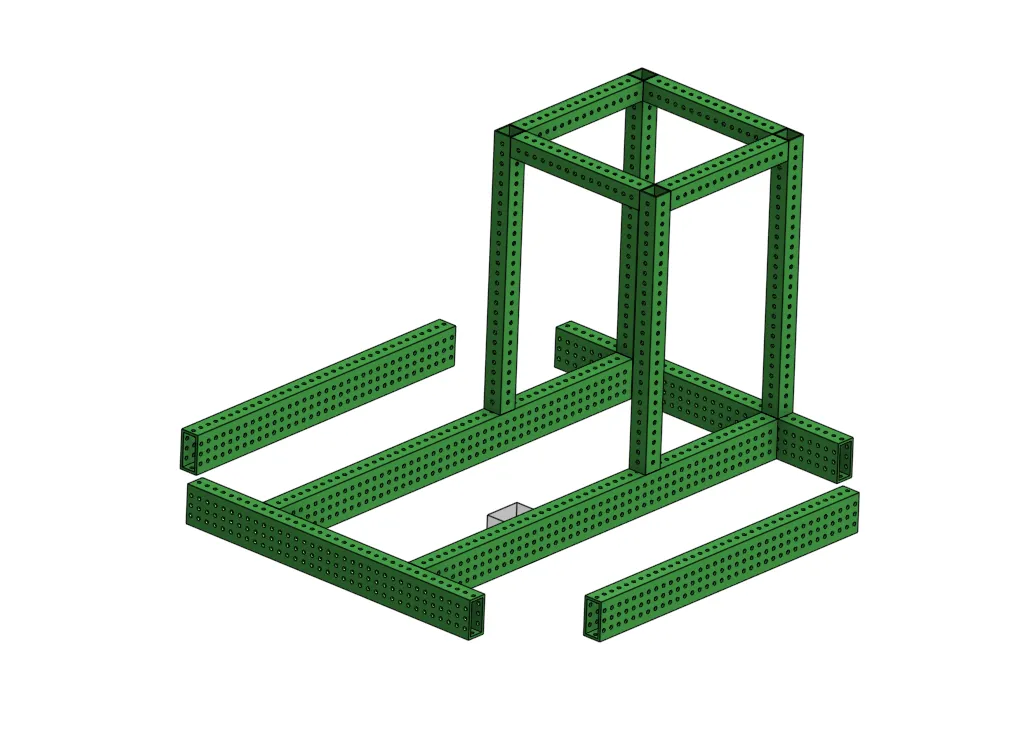

Exercise 5: Building a Box Superstructure

Introduction

Frames made out of box tube can added to the top of a drivetrain for extra mounting for more parts of subsystems, like a shooter or an arm.

In this exercise we'll be adding a simple box tube frame to the drivetrain you made previously.

Layout Sketch and Drivetrain

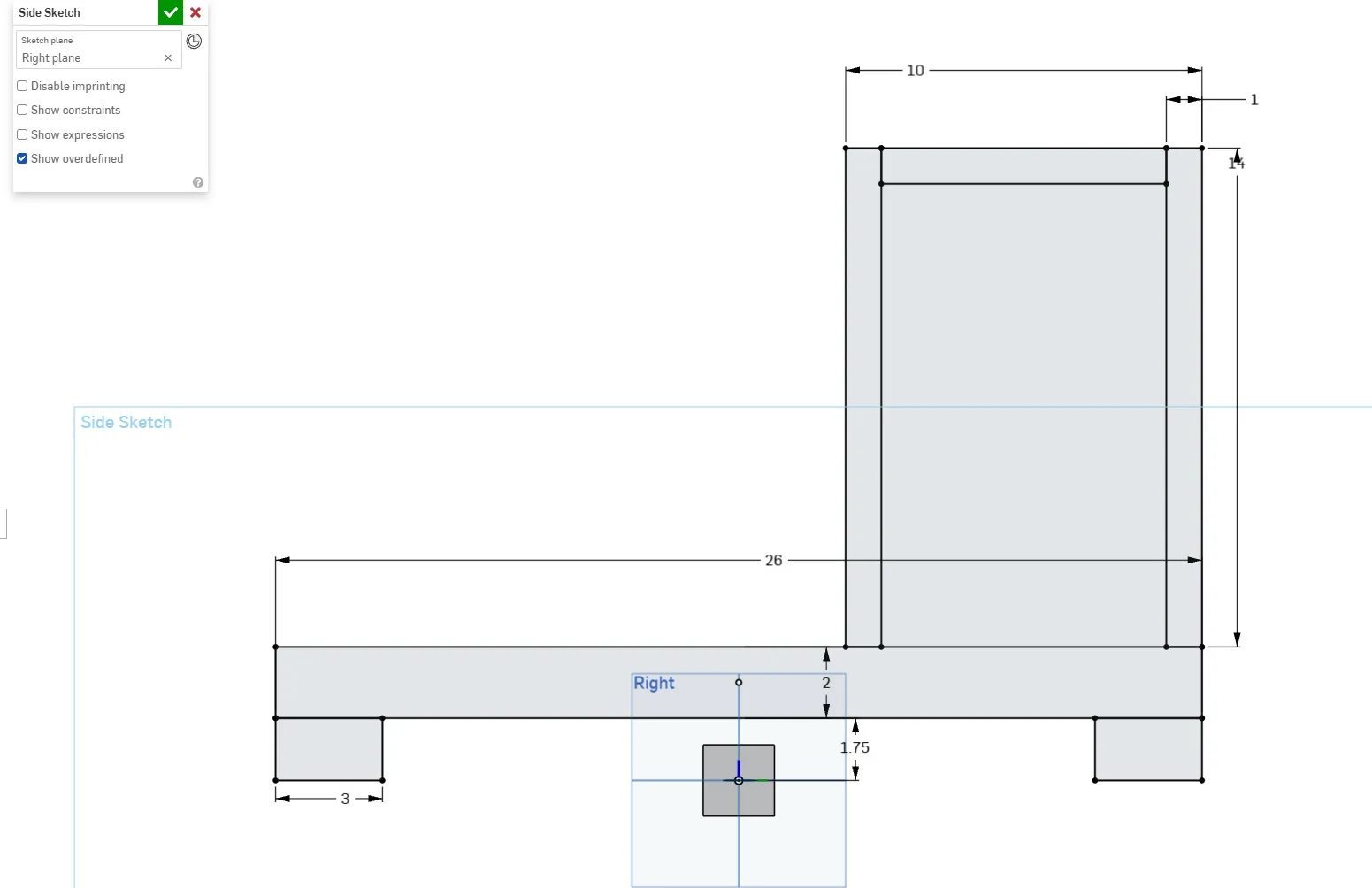

- To properly plan this out, we must create a side layout sketch (the used previously in Exercise 5).

- This step had you insert an orgin cube, Ignore.

-

Make a new sketch, select the

right plane, and start copying this sketch. Figure out the constraints you need yourself to replicate it perfectly.

Box superstructure sketch Origin Placement

The wheels are the 1.75-inch blocks on the corners of the tube. If that's the case, where is the origin placed in the side layout sketch? Why do you think it's placed there? Imagine if you looked at the robot in real life to the side.

-

After the side layout sketch is done, create the swerve drivetrain frame in your part studio according to what you remember from the last exercise. (Remember to select the mate connector!)

Tip

If you struggle, refer to the previous video after trying

Design Intent

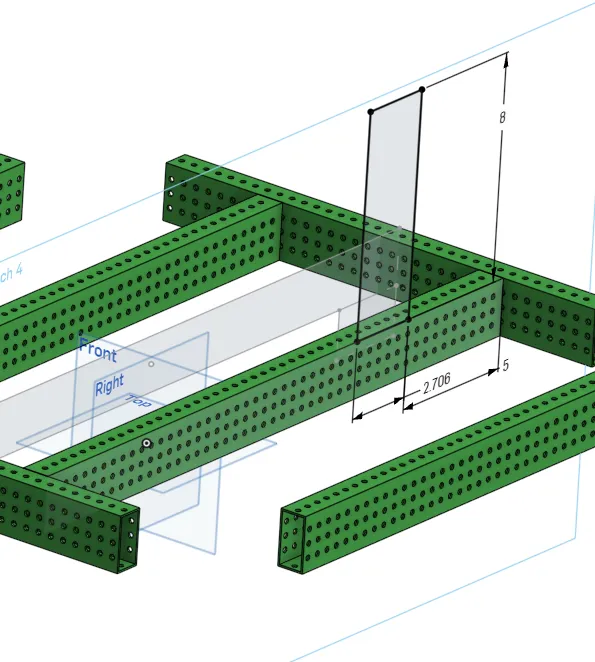

Let’s make this drivetrain a square. How would you approach your top sketch to avoid using any unnecessary dimensions? You should only need to define your swerve gap, the distance between your cross tubes (8 inches), and your tube offset.

Hint

What length is already defined/constrained? Can you use the equal constraint?

Modeling the Frame

So far, sketches have been created on default planes and mate connectors. In order to model the box tube for the frame on top of the cross tubes, the sketch to create the tubes should be created on the face of the cross tube, because that's where you want that tube to be, even if the cross tube changes position.

Design Intent

This is called modeling with "design intent." There are many different ways to model something, but you can choose specific ways based on what your intent for a part or the overall design is. This can also help you avoid creative blocks and keep your CAD from creating errors when the design changes.

Watch a demonstration of this sketching technique below.

Now that you’ve seen a demonstration, try to complete the box tube structure by creating a sketch on the face of the cross tube and projecting lines from the layout sketch into the new sketch with the use tool.

Requirements

- The box frame should be made using 0 new dimensions total, both in the sketch and the extrude

- Edit tube converter to use 1/16" thick walls and change “centered on tube” to “auto offset”

Tube Offsets

The distance between the edge of your tube and your hole differs for drivetrains and typical use. If you use "centered on tube" for your regular box tubes your hole spacing wont be correct. Only use “Centered on tube” for your drivetrain rails!

Finishing Up

Once you finish, take a 5-minute break.

After you come back, try to improve or correct any mistakes you find. Once you finish, compare your workflow with the solution. What thought process led you to do something different?

Follow the short video below to learn how to rename your features, then rename the sketches and features in your part studio. Moving forward, we want to always name our sketches and features.

After you're done renaming your features, move on to the next exercise.

Warning

2823 -- Renaming sktches and features can be helpful and I won't stop you. When designing, especially when you are working on something new or are less experienced you often need to restart or drastivcally change how you are approaching the design. For this reason I would warn you that time may be wasted if you prematurely rename everything. With the design philosophy that these lessons teach, which encourages many parts within one Part Studio, the feature tree can quickly become a mess of features all interacting with different parts. This is one reason we advocate for one part per studio as it keeps the feature tree smaller and easier to work on.